When discussing the design, construction, and operation of industrial facilities, the term “industrial BIM (Building Information Modelling) Design Services” refers to the use of BIM technology in the industrial sector. Industrial constructions including factories, power plants, oil refineries, and other such buildings fall under this category.

BIM is a digital representation of a building or structure, which can be used to create a virtual model of the facility. The virtual model contains information about the design, materials, construction, and performance of the building. This information can be used to optimise the design, reduce construction costs, improve construction efficiency, and enhance building performance over time.

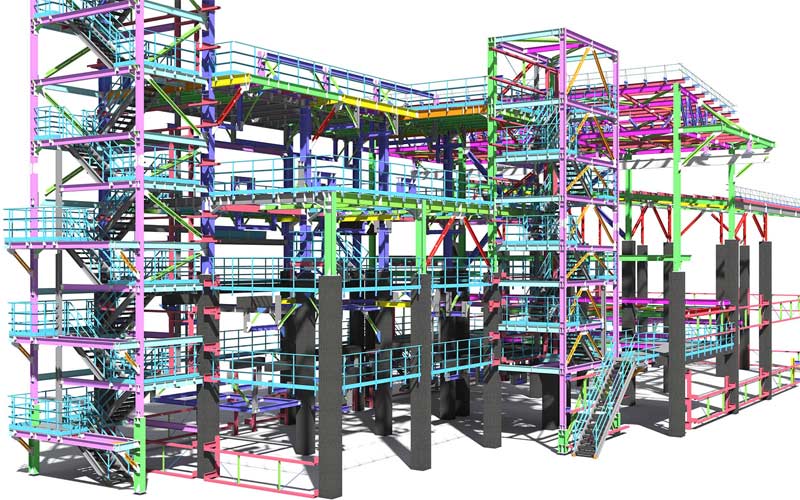

Industrial BIM design services often include the creation of 3D models, simulation of construction processes in 4D, and cost forecasting in 5D. BIM can also be used to develop visualisations, animations, and interactive simulations of the building that can help stakeholders comprehend its design, construction, and intended usage.

3D Modelling

National BIM technology allows for the creation of a 3D virtual model of the industrial complex, complete with all of its components and systems. This model can be used to test numerous design options and visualise the building from various angles in order to discover the optimal design solution. Prior to the start of development, the model can be used to identify any potential conflicts or collisions between different systems and components and to fix them.

4D Simulation

In addition to adding a temporal dimension to the 3D model, BIM may be used to generate a 4D simulation of the construction process. Construction industry personnel can use this to visualise the construction process and test various construction schedules and sequences. This can aid in streamlining the construction process, cutting down on the possibility of delays, and lowering the likelihood of safety accidents.

5D Cost Estimating

A 5D cost estimate, which combines the cost of materials, labour, and equipment into the model, can also be made using BIM. This enables construction industry professionals to comprehend the expenses linked to various design possibilities and to decide on the most cost-effective design solution. This can lower construction expenses and guarantee that the project is completed on schedule and under budget.

Visualisations, animations, and interactive simulations: BIM technology also enables the creation of architectural visualisations, animations, and interactive simulations. These can be used to aid stakeholders in understanding the building’s design, construction, intended use, and appearance and functionality. This can lessen the possibility of misunderstandings and make sure that everyone is in agreement on the structure’s design and construction.

To improve building performance over time, lower construction costs, and increase productivity during construction, a virtual model of the building can be created. BIM is an essential tool for industrial design services as a result.

Piping solutions in BIM Design

Building information modelling (BIM) technology is used to manage and design pipeline systems for construction projects including buildings or other infrastructure. This is referred to as “piping solutions” in BIM design. Piping systems are crucial parts of a variety of structures and infrastructure, such as office, industrial, and residential buildings, as well as water treatment and power plants, among other establishments.

When plumbing systems are designed with BIM, everyone involved works better as a team and with more accuracy and efficiency. BIM can be used to create a virtual model of the plumbing system in order to test and enhance the design as well as to discover and resolve any potential conflicts between different components and systems. Additionally, BIM can be used to supervise all phases of construction, including the on-site installation of the plumbing system.

Plumbing systems may benefit from using BIM in ways like greater design accuracy, better collaboration, better coordination, increased construction efficiency, and enhanced operation and maintenance over time. By decreasing the possibility of design errors, construction delays, and operational issues, these advantages may help to increase the project’s overall efficiency and effectiveness. Using BIM, the piping system’s fluid and gas flow may be exactly recreated, and the system’s performance, functionality, and safety can all be enhanced.

Mechanical solutions in BIM Design

Building information modelling (BIM) technology is used to manage and plan the mechanical systems of a building or infrastructure project as part of mechanical solutions in BIM design. The numerous parts and systems that provide heating, cooling, ventilation, and other environmental control functions in a structure are referred to as mechanical systems. HVAC (heating, ventilation, and air conditioning), plumbing, and fire prevention systems are a few examples of these systems.

BIM results in a more precise and efficient design process when mechanical solutions are applied, as well as enhanced teamwork among all stakeholders. In order to test and refine the design as well as to identify and resolve any potential conflicts between different components and systems, BIM can be used to generate a virtual model of the mechanical system. The management of the construction process, including the on-site installation of mechanical systems, is possible with BIM.

Improved design accuracy, better cooperation, better coordination, increased construction efficiency, and improved operation and maintenance over time are just a few advantages of using BIM for mechanical systems. These advantages may help to lower the possibility of design blunders, construction holdups, and operational issues, as well as to increase the general efficiency and effectiveness of the project. With the use of BIM, it is feasible to precisely simulate the mechanical system’s performance and optimise it for cost-, energy-, and reliability-effectiveness.

Structural solutions in Industrial BIM Design

The structural systems in a building or infrastructure project are managed and designed using building information modelling (BIM) technology. In BIM design, this is referred to as structural solutions. The foundation, walls, beams, columns, and roofing of a structure are just a few of the numerous components and systems collectively referred to as “structural systems.”

Building Information Modelling (BIM) is utilised to develop structural BIM solutions, enabling more precise and effective design as well as greater teamwork among all parties. Testing and improving the design, identifying and resolving any potential conflicts between various systems and components, and testing and improving the structural system are all possible using BIM. Every stage of construction, including the on-site installation of the structural system, may be managed with BIM as well.

Improved design accuracy, better collaboration, better coordination, increased construction efficiency, and improved operation and maintenance over time are just a few advantages of using BIM for structural solutions. These advantages may help to lower the possibility of design blunders, construction holdups, and operational issues, as well as to increase the general efficiency and effectiveness of the project. BIM can be used to precisely mimic a building’s structural performance and optimise the structural system for cost-effectiveness, safety, and stability.

Modular Process Units solutions in BIM Design

The term “modular process unit solutions in BIM design” refers to the planning, simulating, and supervising of the construction of modular process units for a variety of industrial BIM and commercial purposes. Modular process units, which are prefabricated pieces or systems, are produced off-site, transported, and then installed on-site. Pipes, electrical systems, process equipment, and control systems are just a few examples of the items that these units might include.

The design process may be more accurately and successfully completed when BIM is used for modular process unit solutions, and teamwork may be improved. To test and refine the design as well as find and resolve any potential conflicts between various systems and components, BIM can be used to generate a virtual model of the modular process units. BIM can also be used to oversee the delivery and installation of modular process units at the job site as well as other aspects of the construction process.

A multitude of benefits, including enhanced design correctness, increased cooperation, better coordination, increased construction efficiency, and improved operation and maintenance over time, may result from incorporating BIM into modular process unit solutions. These benefits may contribute to improving the project’s overall efficiency and effectiveness by lowering the likelihood of design mistakes, construction delays, and operating problems.

Why are Piping, Mechanical, Structural, and Modular Process Units solutions useful for BIM Design?

Piping, Mechanical, Structural, and Modular Process Units solutions are useful for BIM design for several reasons:

- Improved Design Accuracy: BIM permits the creation of a virtual model of the building’s systems and components in order to assess and enhance the design. It is possible to more properly represent piping, mechanical, structural, and modular process units using BIM, which reduces the potential of design errors and guarantees that the design is optimised for use, safety, and efficiency.

- Enhanced Collaboration: BIM enables real-time collaboration among all project team members, including architects, engineers, contractors, and owners. BIM can be utilised for piping, mechanical, structural, and modular process units to make sure that everyone is in agreement with regard to the design, construction, and use of diverse elements and systems. By doing so, the likelihood of misunderstandings and miscommunications can be reduced, and the project’s overall efficacy can rise.

- Better Coordination: All building systems and parts, such as the plumbing, mechanical, structural, and modular process modules, can be coordinated thanks to BIM. By doing so, you can make sure that the design is optimised for use, safety, and efficiency as well as detect and resolve any potential conflicts between various systems. Using BIM for these parts and systems can also help to lower the possibility of construction mistakes, which can speed up and reduce the cost of the construction process.

- Improved Construction Efficiency: In order to optimise the construction process and lower the possibility of delays, BIM enables the production of a 4D simulation of the construction process. BIM can be used to ensure that plumbing, mechanical, structural, and modular process modules are placed properly and lower the risk of safety accidents during construction. Additionally, the use of BIM can help to cut down on the time and expense of rework because possible issues can be found and fixed before construction ever starts.

- Better Operation and Maintenance: BIM can be used to create a virtual model of the building, which can be used to understand how the building will operate and be maintained throughout time. BIM can assist in reducing the risk of operational issues and improve overall building performance by ensuring that plumbing, mechanical, structural, and modular process units are maintained effectively throughout time. Additionally, using BIM for these components and systems allows for effective and efficient maintenance and repair work, ultimately saving both time and money.

The use of BIM for piping, mechanical, structural, and modular process units solutions is valuable because it allows for a more accurate representation of these components and systems, enhanced collaboration, better coordination, improved construction efficiency, and better operation and maintenance over time.

Who can help with BIM Design services?

A multitude of benefits of BIM, including enhanced design correctness, increased cooperation, better coordination, increased construction efficiency, and improved operation and maintenance over time, may result from incorporating BIM into modular process unit solutions. These benefits may contribute to improving the project’s overall efficiency and effectiveness by lowering the likelihood of design mistakes, construction delays, and operating problems.

It’s crucial to pick a business or individual with BIM design expertise and a track record of completing successful projects. The business or expert should be knowledgeable about both the latest BIM technologies and tools as well as the particular project requirements.

When selecting a business or specialist, the cost of the BIM design services must be taken into account. Pricing policies may vary amongst businesses, and some might provide more complete services than others. To choose the one that best meets the needs of your project, it is crucial to compare the services and prices offered by several businesses and professionals.

Why should I use an Industrial BIM Design expert?

- Improved accuracy: BIM specialists can provide extremely precise designs thanks to their in-depth expertise of BIM technology and its potential. Through the use of BIM, they may create a 3D model of the building or infrastructure project and find any potential problems before work ever starts. This lowers the possibility of errors and guarantees that the design satisfies your unique requirements.

- Enhanced collaboration: BIM professionals are aware of the value of teamwork and are capable of cooperating successfully with other members of the project team, such as architects, engineers, and contractors. They can also offer a central location for all project data that all stakeholders can view, guaranteeing that everyone has access to the same data. This can aid in reducing misunderstandings and disagreements and enhancing general communication among all project team members.

- Better coordination: To coordinate the design and construction of various parts of the building or infrastructure project, BIM specialists can use BIM technology. Additionally, they can find and resolve any potential conflicts between various systems prior to the start of development. This lessens the possibility of delays and added expenses while ensuring that all systems operate in unison.

- Improved construction efficiency: BIM specialists can employ BIM technology to streamline the building process, lowering the possibility of delays and ensuring that the project is finished on schedule and under budget. They can use BIM to mimic the construction process, spot any problems, and fix them before work starts. By doing so, the possibility of construction delays can be decreased, and total construction efficiency can be increased.

- Better operation and maintenance: The facility may be kept in top condition throughout time by using the specific information that BIM professionals can provide regarding the construction of the building or the infrastructure project. With the use of BIM, they are able to produce a virtual representation of the construction site or infrastructure project that contains all pertinent data, such as the locations of all systems, machinery, and other components as well as their requirements. The danger of operational issues can be decreased with the use of this information, which will also boost facility performance in general.

- Cost savings: BIM specialists can find potential for cost savings and contribute to lowering the project’s overall cost by employing BIM technology. For instance, they can use BIM to optimise the design and find and fix any potential problems before building starts. By doing so, the possibility of bad design decisions and construction delays can be reduced, thus saving money.

Your building or infrastructure project can gain a lot from working with a BIM design professional, including increased accuracy, improved cooperation, better coordination, increased construction efficiency, improved operation and maintenance, and cost savings.

Are BIM Design Services expensive?

The cost of BIM design services could vary greatly. The project’s size and complexity, the quantity and calibre of the information required, and the training and experience of the BIM design expert can all affect how much BIM design services cost.

BIM design services are often regarded to be more expensive than traditional design services since BIM technology requires a higher level of aptitude and understanding to work efficiently. Although the costs of BIM design services may be higher, the benefits it offers—such as greater accuracy, better cooperation, better coordination, higher construction efficiency, better operation and maintenance, and cost savings—might offset those costs.

BIM can also assist in lowering the overall cost of a building or infrastructure project by seeing opportunities for cost savings, lowering the likelihood of errors, and speeding up the construction process.

Ultimately, the cost of BIM design services will depend on your specific project requirements and the services you require. It’s best to speak with a BIM design expert or a consulting firm to get a more accurate estimate of the cost of BIM design services for your project.

BIM Design for industrial construction project needs

BIM design is a valuable tool for industrial construction projects, as it can provide a number of benefits, including:

- Improved accuracy: Using IM, a highly accurate 3D model of the industrial construction project may be created. This model can be used to improve the general soundness of the design and spot any issues.

- Enhanced collaboration: To ensure that all stakeholders have access to the same information, BIM can be used to establish a central repository for all project data that can be accessible by all parties. There may be fewer misunderstandings and disagreements as a result, and the project team as a whole may communicate better overall.

- Better coordination: BIM makes it possible to coordinate the design and construction of different industrial construction project components, guaranteeing system compatibility and lowering the likelihood of delays and added expenses.

- Improved construction efficiency: BIM can be used to hasten the construction process, lessen the possibility of delays, and ensure that the project is finished on schedule and under budget.

- Better operation and maintenance: BIM might provide detailed information on the industrial construction project that could be utilised for ongoing operation and maintenance to keep the facility performing at its best.

- Cost savings: By lowering project costs overall and assisting in the identification of cost-saving possibilities, BIM helps to decrease the possibility of mistakes and construction delays.

In addition to these advantages, National BIM may offer a more eco-friendly option for industrial building projects by assisting in the optimisation of energy consumption and waste reduction, which enhances the project’s overall sustainability.

BIM design is more important than ever for industrial building projects since it offers a number of advantages that can increase the project’s accuracy, efficiency, and sustainability. If you want to know more, Contact Us today and allow us to help you with BIM Design.